The Challenge: Beyond “Myopic” Robotics

Stroke remains a leading cause of long-term disability, with over 800,000 cases annually in the U.S. alone. While robot-assisted rehabilitation offers a scalable solution to the shortage of physical therapists, a critical requirement for neuroplasticity is "active effort." If a robot does all the work, the patient remains passive, and no motor learning occurs.

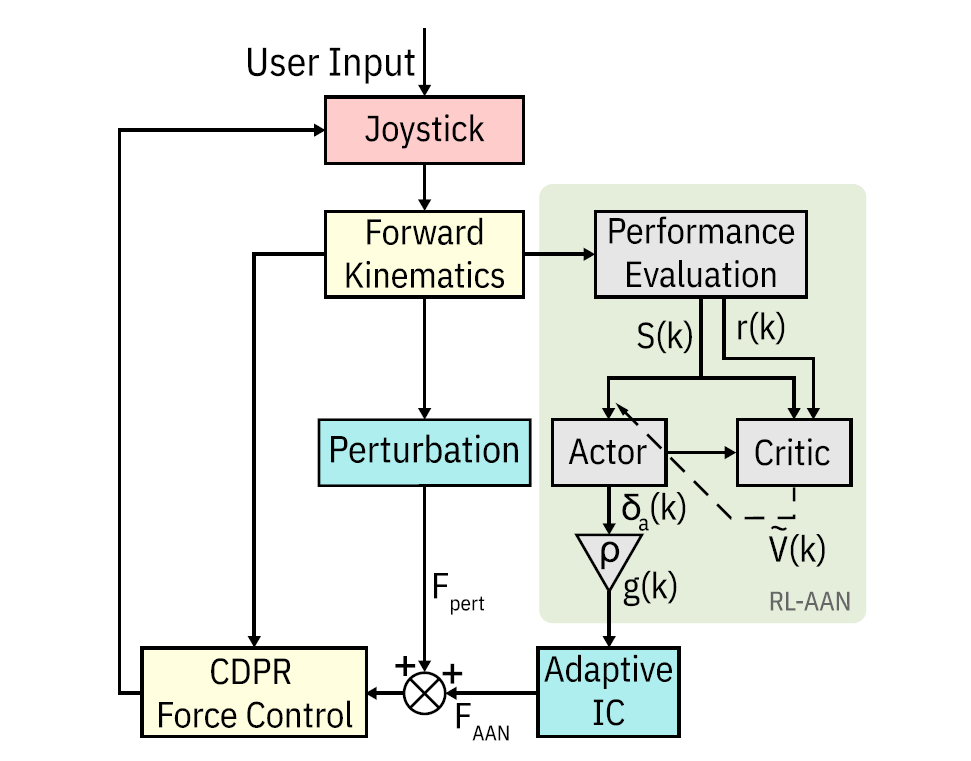

Professor Damiano Zanotto and his team at Stevens Institute of Technology sought to solve this by developing a "smart" robotic system using Reinforcement Learning (RL). They hypothesized that a controller could "learn" the patient's needs in real-time—offering support only when necessary (Assist-as-Needed) and forcing effort when possible.

The Hurdles: The Gap Between Theory and Hardware

Moving from a theoretical control algorithm to a physical machine presents two distinct hurdles: technical and financial.

- Technical Latency: Traditional "myopic" controllers are reactive, adjusting only after an error occurs. The Stevens Institute team needed a system capable of "Curriculum Learning"—processing neural network outputs and adjusting motor torque instantly (at 1 kHz) to keep the patient in the optimal learning zone.

- The Academic Constraint: Validating a new theory requires high-performance, industrial-grade components. However, academic budgets are frequently strained. Researchers often face a difficult trade-off: compromise on hardware performance to save costs, potentially invalidating their results, or stall the project due to lack of funding.

The Solution: A Partnership for Innovation

To bridge the gap between theory and practicality, the team utilized the ADVANCED Motion Controls University Outreach Program.

Professor Zanotto and Stevens Institute of Technology had previously worked with AMC's University Outreach Program for a haptic joystick project several years before. So when this project needed a servo drive, Professor Zanotto knew exactly who to call.

Recognizing the project's potential contribution to the medical community, AMC donated DZEANTU-020B200 digital servo drives to the lab. This partnership provided the team with industrial-grade hardware without the prohibitive costs, allowing them to focus on the engineering challenge rather than procurement limitations.

The Hardware Advantage:

The DZEANTU drives were integrated into a custom Cable-Driven Parallel Robot (CDPR).

- High-Speed Communication: The drives communicated with the real-time target machine via EtherCAT, achieving the critical 1 kHz update rate required by the RL algorithms.

- Precision Control: The digital drives provided the precise current loop control necessary to render smooth, haptic forces, making the robot feel like a natural extension of the therapist.

The Results: Validated Success

With the financial burden eased and the technical requirements met, the team successfully validated their Reinforcement Learning Assist-as-Needed (RL-AAN) controller. The study showed that users trained with the AMC-powered system demonstrated:

- Reduced Robot Dependence: Users were forced to contribute significantly more active effort than with traditional controllers.

- Superior Retention: Users retained better trajectory accuracy even after robotic assistance was removed.

By getting high-performance servo drives into the hands of these researchers, ADVANCED Motion Controls became an integral part of a project that pushes the boundaries of stroke recovery.

About the University Outreach Program

Since 2004, ADVANCED Motion Controls has partnered with students, researchers, and professors to further the educational process in motion control. Our objective is to ease the financial burdens of establishing practicality while proving theory.

Whether you are working on a master’s thesis, a classroom project, or a laboratory upgrade, we are proud to become a pending part of your team. We offer:

- Donated or Discounted Equipment: From new servo drives to perfectly functional discontinued units from our "free drives list."

- Technical Support: Direct access to our engineering team to help you select the best product for your specific application.

- Real-World Experience: Putting industrial-grade equipment into the hands of future engineers.

Have a project? Tell us about your mission.

Contributions are typically limited to U.S. institutions or international projects involving U.S. institutions.