For the past several years, the story of servo drive development has been a relentless pursuit of power density. The primary challenge was clear: pack more power into a smaller package. While that mission continues, the industry is entering a new phase of maturation. In 2025, the most significant trends aren't just about raw performance, but about the intelligence, safety, and reliability of the entire motion control system.

It’s a shift from brute force to finessing the details that make complex machine design faster, safer, and more dependable. Here’s what we see defining the year ahead.

The Maturation of Integrated Safety

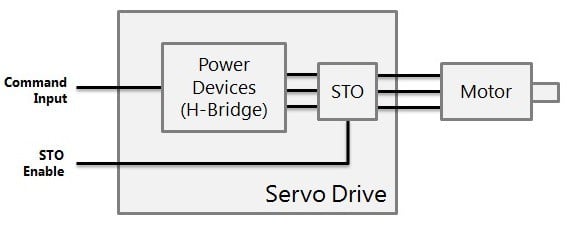

Functional safety is no longer an afterthought addressed with external components. It’s becoming a core, integrated part of the drive itself. We expect to see Safe Torque Off (STO) certification become a baseline feature across a wider range of servo drives in 2025, providing a certified, reliable method for ensuring motor torque is disabled in a safety event.

Beyond the increasing availability of STO, we are continuing to work toward adding a more comprehensive suite of safety functions to our drives. This deep integration is essential for building the next generation of collaborative and human-interactive machinery with confidence.

Reliability by Design, Not by Chance

For engineers, a drive’s performance on a datasheet is meaningless without the assurance of its long-term reliability in the field.

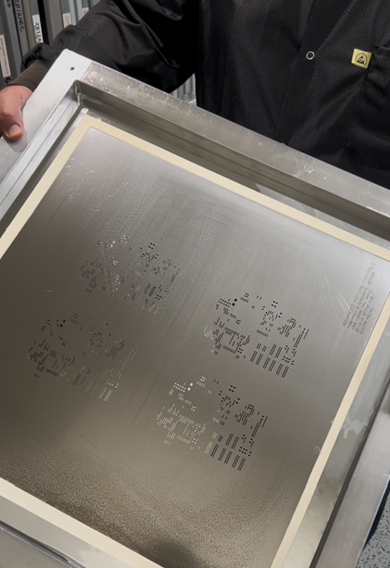

A key, often invisible, trend is the intense internal focus on Design for Manufacturability (DFM). Assuming corners aren't cut, robust design for manufacturability lends itself to a product's robustness overall.

A rigorous DFM philosophy means optimizing every aspect of the drive’s design for consistency and robustness during production from selecting components with a stable, multi-source supply to designing layouts that prevent common assembly faults. The direct result is a more resilient product and a more stable supply chain, ensuring the hardware you depend on performs consistently from the first unit to the thousandth.

Do you like this article?

Get blogs like this delivered directly to your inbox!

System-Level Simplicity: Less Integration, More Innovation

Engineers have spent too much time acting as component integrators trying to find ways to fit square pegs in round holes. The industry is moving to solve this by simplifying the system architecture. We see this in two key areas:

-

Custom-Engineered Multi-Axis Solutions

Designing a coordinated motion system with three or four separate drives means complex wiring, oversized cabinets, and wasted energy. The trend is moving toward custom-engineered solutions that combine multiple drive axes into a single unit with a shared power bus. This custom-built approach is the elegant solution. It simplifies design, shrinks machine footprints, and improves energy efficiency by sharing regenerative power between axes.

-

Strategic Partnerships:

The performance of a servo system depends on the synergy between the drive, motor, and feedback device. To eliminate the risk and time spent on component matching, deep partnerships between manufacturers are becoming crucial. The result is pre-validated, optimized pairings that allow you to focus on your application’s core innovation, not on troubleshooting basic compatibility. When you browse our 3rd Party Compatibility, our P3 (Preferred Product Partners) are examples of these kinds of partnerships.

Unlocking New Applications with Advanced Capabilities

While system-level improvements are key, new capabilities continue to expand what’s possible. Higher voltage drives (approaching the 200VDC class) are enabling smaller motors to achieve higher speeds, opening new possibilities for high-speed robotics and automation.

Simultaneously, the adoption of Dual Universal Feedback is allowing engineers to solve mechanical challenges with elegant software solutions.

For years, many servo drives have supported dual loop feedback, allowing them to process signals from two encoders at once, such as a primary encoder on the motor and an auxiliary encoder on the final load. These drives intelligently compensate for mechanical issues like backlash or belt compliance. This creates a system with higher precision without the cost and complexity of over-engineering the mechanics.

Dual Universal Feedback takes this a step further. The "universal" trend provides flexibility, allowing engineers to programmatically assign inputs and mix-and-match feedback types as needed. For example, the motor might use an incremental encoder while the load uses an absolute encoder.

Human Expertise: The Ultimate Feature

In an interesting paradox, as motion control systems become more automated and complex, the value of direct access to human expertise has never been higher. When facing a novel control challenge on a tight deadline, nothing replaces a conversation with an experienced applications engineer who understands the nuances of the real world. In 2025, we believe that investing in top-tier, accessible human support is not just good customer service; it’s one of the most critical features a component manufacturer can offer.

As we move into the new year, the evolution of the servo drive is about building a more complete and dependable ecosystem; one that empowers engineers to design with more speed, confidence, and creativity than ever before.

by René Ymzon, Marketing Manager

Do you like this article?

Get blogs like this delivered directly to your inbox!